Which filling system does your product prefer?

Cold, hot or aseptic? And what would you like your filling system to provide? That it fills with a great deal of precision and a low amount of foam? That it gently fills your product into the bottle while simultaneously protecting it from oxygen? That it remains flexible for different formats and also knows how to treat lightweight bottles?

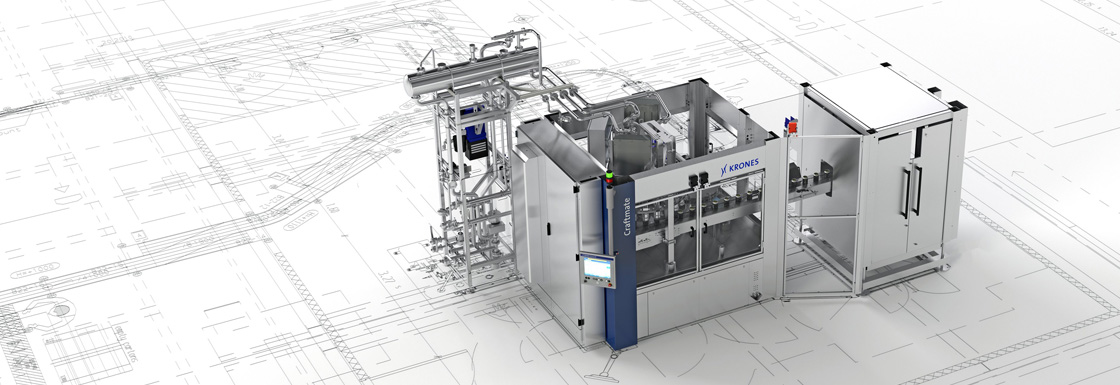

Regardless of which of these points and how many of them are important to you for your filling process – with Krones filling systems you will find just the right technology to suit every taste. From the filling method and output, through to the level of hygiene: Krones specialists will be only too pleased to provide you with advice on the best system to use in your bottling line.