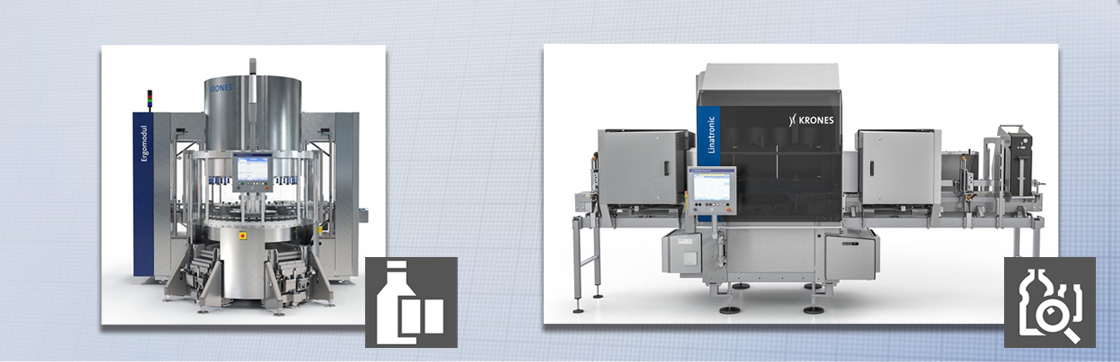

Labelling and Inspection Technology

With machines of Krones from the lines labelling- and inspection technology, you can be sure that your product will convince at first sight! Use our decades of experience to your advantage!

Here in the Krones.shop you can now request your desired machine type easily and without obligation. Simply use the form below and you will receive your customized offer within a short time.

Request labelling and inspection solutions now in just a few steps!

1. Click the "Request now" button.

2. Select your desired product specifications in the inquiry form.

3. Enter your customer data.

4. By clicking on "Request for quotation" you can send your request.

Your inquiry will be forwarded directly to our experts. They will contact you shortly to discuss further details. We look forward to hearing from you!