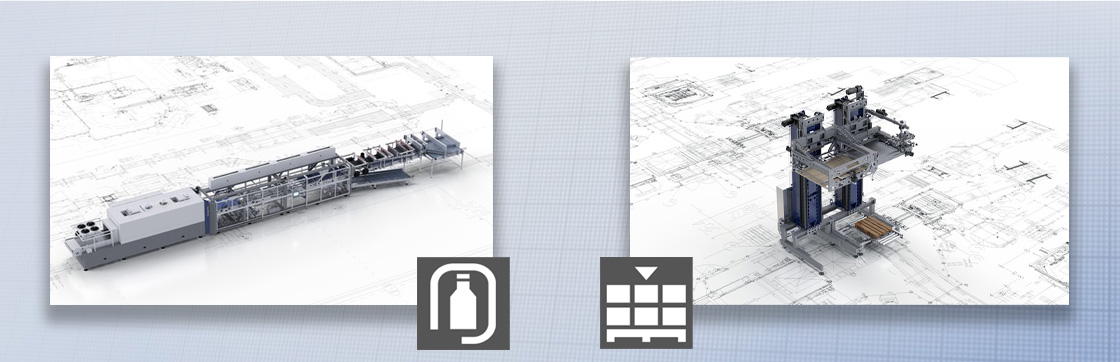

Packaging and Palletising Technology

Leaves nothing to be desired ‒ Krones packaging technology

The diversity of the packaging world knows almost no limits.

With Krones, you have a partner at your side who has decades of experience with packaging diversity and who is happy to share it with you.

You benefit from sophisticated machine technology that also masters complex packaging solutions, as well as from our packaging consulting, if you wish.

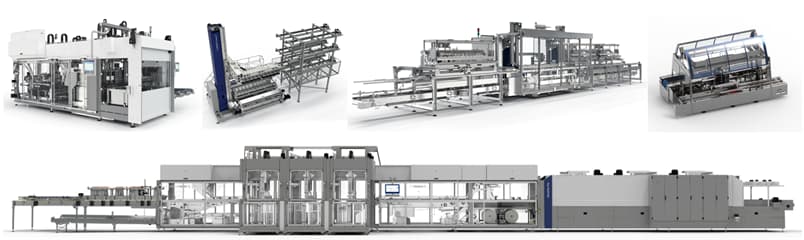

For everyone who aims high ‒ Krones palletising technology

The selection of the right palletising system not only takes into account the required performance range and the type of packs to be processed.

The infeed height and the desired layer schemes as well as the space available also influence the selection of the palletising system.

In addition, packaging materials processing is often required.

Krones palletising technology definitely covers the entire range of requirements.

Packaging technology

Solutions for packaging in secondary and tertiary (disposable and returnable) packaging

The machines at a glance

Crates and RSC boxes:

- Contipac – compact machine for the medium performance range (packer/unpacker)

- Smartpac – high performance (packer/unpacker)

- Linapac II – particularly suitable for a wide processing spectrum and high performance (packer/unpacker)

LitePac Top, shrink packs, trays and wraparounds:

- Variopac Pro – different types of packaging that can be combined in one machine

Packaging line:

- Varioline – particularly suitable for processing cluster-/multipacks and secondary and tertiary packaging in one machine

Palletising technology

Solutions for grouping, loading and unloading packs as well as sweeping-off bulk containers

The machines at a glance

Disposable packs (RSC box, wraparound, tray, shrink, shrink tray, shrink pad):

- Modulpal Pro 1A, 1AD, 1AH, 2AC, 2ADP, Pressant Universal 1N

Disposable and returnable packs (crates):

- Modulpal Pro 2A, 3A, 3AR, Robogrip 4A

Returnable packs (loading and unloading):

- Pressant Duplex 2NT

Bulk container handling:

- Pressant Universal 1A and 1N

Combi machine (packing & loading):

- Modulpal Pro 2A, 3A, 3AR, Robogrip 4A

Grouping:

- Robobox, conventional 90°

Selected highlights from packaging technology

- Fully automatic handling parts change-over for Linapac II

- Spindle-adjustable gripper head for Linapac II and Smartpac (optional)

- Case opener / closer can be integrated in Contipac (optional)

- LitePac Top processing and tertiary packs available in one machine (Variopac Pro)

- The Varioline can fulfill a large number of machine functions and requires incredibly little space

Selected highlights from palletising technology

- High and low infeeds available

- Packaging material handling can be integrated

- Grouping by gantry robot or tripod

- Highest performance available

- Palletising by means of an articulated arm robot, scara robot or layer palletiser

Request packaging and palletising solutions now in just a few steps!

1. Click the "Request now" button.

2. Select your desired product specifications in the inquiry form.

3. Enter your customer data.

4. By clicking on "Request for quotation" you can send your request.

Your inquiry will be forwarded directly to our experts. They will contact you shortly to discuss further details. We look forward to hearing from you!