Optimized shrinking result, improved sustainability and reduced costs... it all starts with the Krones film analysis!

Optimized shrinking result, improved sustainability and reduced costs... it all starts with the Krones film analysis!

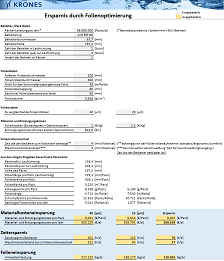

Reduce your costs by optimizing the shrink film you use. Save costs by reducing the used film thickness, by reducing the film overlap of your packs or by reducing the lateral film overhang.

With our savings calculator you can calculate your individual savings by changing the parameters film thickness, film overlap and film overhang. You do not just save material, disposal and packaging licensing costs, you also increase your output by reducing machine downtime due to less frequent film roll changes.

Operator involvment is also reduced by extending the film change intervals.The savings on shrink film are also calculated. Thus, the contribution to more sustainability can be represented by a smaller ecological footprint and the improvement of the environmental balance.

A better shrinking result means a more attractive product appearance, which can increase the demand. However, a better shrinking result can also have positive influence on the stability of production and thus on output. The number of factors influencing the shrinking result is enormous. A change of supplier, for example, can have an effect on the shrinking result even when the film appears to be the same.

Material properties such as shrinking rates, shrinking force, surface tension, coefficient of friction, sealing properties, elongation at break and film thickness are examples of parameters that influence the shrinking result. However, the ratio of printed to unprinted area and even the choice of printing inks can also change the shrinking result.

The amount of film processed has a major influence on sustainability. But also, material origin and -composition have an increasingly important role in the public debate. For this reason, the question of the recycling rate of a shrink film is also gaining in importance. There is also growing interest in films made from renewable raw materials or films that are biodegradable.

However, a change of the used film has always an impact on the packaging process. Every plant operator is therefore well advised to check the effects on the production process before changing to a different, more sustainable film and, if necessary, to adjust the configuration of the packaging machine.

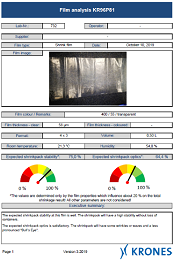

With Krones film analysis, you as the plant operator have the opportunity to clarify in advance how the new film you are considering will affect the production process. For this purpose, all relevant film parameters are examined and evaluated within the scope of Kronesfilm analysis. The results are clearly displayed using speedometer diagrams with traffic light evaluation. In addition, a comprehensible verbal summary of the results is provided. The Krones film analysis provides answers to the questions:

*If necessary, the planned changes require a retrofit of the packaging machine. We will be pleased to make you an offer for this on request.